When considering the iPhone 6s production cost, it’s fascinating to see how Apple has effectively balanced innovation with affordability. Despite introducing advanced features like 3D Touch and a powerful A9 processor, the total production expense remains surprisingly similar to previous models. In fact, analysis suggests that the components used for the Apple iPhone 6s only amount to about $234. Understanding the cost to build iPhone 6s sheds light on the meticulous planning behind every model Apple releases, from semiconductor parts to the intricate camera systems. This breakdown not only highlights Apple’s manufacturing strategies but also reveals the intricate relationship between costs and pricing in the highly competitive smartphone market.

The manufacturing expenses associated with the Apple iPhone 6s have intrigued tech enthusiasts and industry analysts alike. Delving into the cost associated with creating the iPhone 6s reveals how Apple maintains its pricing strategy through intelligent component sourcing and assembly practices. By examining the overall financial outlay—encompassing semiconductor components, cellular radios, and memory technologies—we can further appreciate the complexities of Apple’s product development. The efficient allocation of resources in building the iPhone 6s demonstrates how even with the latest features, Apple can hold the iPhone 6s price breakdown steady. Exploring the financials behind such consumer electronics helps shed light on the broader implications of pricing in technology.

Understanding iPhone 6s Production Cost

The production cost of the iPhone 6s has been a subject of much discussion, particularly given the advanced features it offers. According to estimates, Apple will invest about $234 solely on parts for the device. This figure has remained consistent with previous models, showcasing the company’s knack for keeping manufacturing costs in check while introducing technological advancements such as the A9 processor and 3D Touch. With additional expenditure on assembly and testing that is estimated between $8 and $11 per device, the overall cost to build the iPhone 6s climbs to about $250.

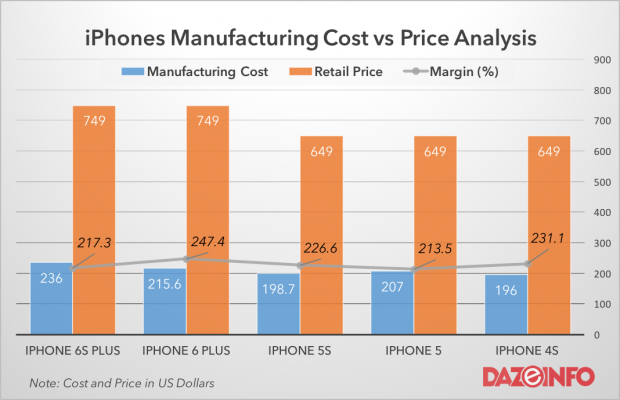

This cost analysis reveals Apple’s operational efficiencies in managing production. By strategically sourcing more economical components and maintaining quality in manufacturing, Apple creates a balance between pricing and profitability. Interestingly, even amidst heightened competition in the smartphone market, Apple has maintained a price point of $749 for the unlocked 64GB version, allowing it to enjoy a healthy margin over the production costs. The breakdown thoughtfully illustrates how Apple has remained competitive while ensuring quality features that appeal to tech-savvy consumers.

Breakdown of iPhone 6s Features

The Apple iPhone 6s comes equipped with a range of features that not only enhance user experience but also contribute significantly to its overall production cost. With cutting-edge technologies like a front-facing flash and advanced sensors for NFC and fingerprint scanning, the iPhone 6s represents a leap forward in smartphone capabilities. These features, while increasing initial manufacturing costs, enhance the device’s marketability, driving consumer interest and demand.

When we look at the production cost breakdown, we find that components like the new A9 processor and 64GB flash memory play a crucial role in both the performance and expense of manufacturing the iPhone 6s. This investment in high-quality parts translates into a device users are willing to pay for, reinforcing Apple’s brand reputation for quality and innovation in technology.

Apple Manufacturing Costs Explained

At the heart of Apple’s pricing strategy lies an intricate understanding of manufacturing costs. For the iPhone 6s, Apple’s management has clearly outlined its expenditure on components, packaging, and assembly processes. The estimated cost of $250 per device, accounting for parts and labor, exemplifies the meticulous planning that goes into bringing each iPhone to market. Understanding these underlying costs is essential for consumers and investors alike, as it sheds light on Apple’s profit margins and overall business strategy.

Moreover, Apple’s relationship with suppliers and assembly partners like Foxconn is critical in maintaining operational efficiency. By keeping assembly costs to a modest level while ensuring high production quality, Apple effectively navigates the balance of price and performance. Such strategic choices underscore how manufacturing costs are foundational to Apple’s pricing model for the iPhone 6s and other devices in its lineup.

iPhone 6s Price Breakdown: What Consumers Should Know

The retail price of the iPhone 6s, label at $749 for the 64GB version, reflects more than just the parts that go into the device. Understanding the price breakdown reveals several factors that influence this cost, including manufacturing, distribution, and marketing efforts. Although Apple spends approximately $250 to produce each phone, the additional expenses incurred through distribution channels, promotional strategies, and retailer margins contribute to the final retail price.

This comprehensive approach to pricing allows Apple to sustain profitability while offering devices that are well-received in the marketplace. Moreover, discerning consumers can grasp how these pricing structures support ongoing innovation. The continued investments in enhancing features and functionalities, despite cost increments, help retain customer loyalty and ensure Apple’s competitive edge.

Advanced Features of the Apple iPhone 6s

Innovations such as the A9 processor and 3D Touch technology not only enhance the performance of the iPhone 6s but also demystify some of the production costs associated with these advanced components. Each feature adds significant value, compelling consumers to pay a premium for the experience. The operational enhancements that come with these features affirm Apple’s commitment to integrating cutting-edge technology into their devices.

In addition, features like the upgraded camera and improved battery life represent strategic improvements made without drastically inflating the overall production cost. These innovations are aimed at delivering a superior user experience, ensuring that customers perceive their investment in the iPhone 6s as worthwhile.

Apple’s Strategic Cost Management

Apple’s approach to cost management is noteworthy, especially considering the competitive landscape of smartphone manufacturing. By keeping the manufacturing cost of the iPhone 6s around $250, which is just marginally higher than its predecessor, Apple has demonstrated a keen ability to innovate without significantly raising production costs. This efficiency is achieved through rigorous supplier management and cost-analysis practices.

Apple’s management also focuses on streamlining production processes and making judicious use of technology in manufacturing. This not only leads to reduced costs but also enables quicker transitions to new product lines, allowing Apple to maintain its status as a leader in the tech industry.

Comparative Analysis of iPhone 6s and Previous Models

When comparing the iPhone 6s to its predecessors, it’s evident that Apple has maintained a careful balance between enhancing features and controlling production costs. The inclusion of features like 3D Touch and an upgraded A9 processor marks a substantial technical leap; however, the actual cost to build the iPhone 6s does not differ dramatically from older models. This aligns with Apple’s ongoing strategy to ensure that each new device remains affordable while appealing to tech enthusiasts.

This consistency in production cost amidst innovation is emblematic of Apple’s broader philosophy. By maintaining similar or slightly higher manufacturing costs for newer models, Apple can consistently deliver high-value products that meet consumer expectations without alienating its pricing structure.

Impact of Production Costs on iPhone Pricing Strategy

Production costs wield considerable influence on pricing strategies for products like the iPhone 6s. With the base production cost pegged at around $250, which still leaves a wide margin before reaching the retail price of $749, Apple has room to play with pricing strategies. Differentiation through high-quality production allows Apple to justify its premium pricing model, even amid aggressive competition.

Consequently, insights into production costs can provide valuable understanding into Apple’s overall pricing outlook. This insight is particularly relevant in discussions around pricing accuracy and market position, suggesting that Apple’s high loyal customer base is deeply rooted in its ability to effectively manage production expenses while delivering innovative technology.

Future Trends in Mobile Manufacturing Costs

As technology evolves, the future trends in mobile manufacturing costs are likely to shift in significant ways. Manufacturers, including Apple, will need to navigate challenges related to material costs, assembly labor, and advancements in technology. The introduction of new functionalities, such as augmented reality or advanced artificial intelligence capabilities, may lead to rises in production costs, although innovations may also present opportunities for cost efficiencies.

Moreover, the ever-tightening competition in the smart device arena necessitates a focus on agile manufacturing processes. Apple’s experience with the iPhone 6s could offer valuable lessons, particularly regarding how to implement cost-effective strategies without compromising quality in the face of rising costs. Such consideration will be critical in shaping the pricing and product offerings for future generations of smartphones.

Frequently Asked Questions

What is the iPhone 6s production cost compared to its price?

The iPhone 6s production cost is estimated at around $250, which is $20 higher than the previous iPhone 6. This production cost includes materials, assembly, and other manufacturing expenses, while the retail price for an unlocked 64GB iPhone 6s starts at $749.

How does Apple manage the iPhone 6s production costs despite advanced features?

Apple has managed to maintain the iPhone 6s production costs by optimizing component sourcing and manufacturing processes. Despite the inclusion of advanced features like 3D Touch and enhanced processors, the cost to build the iPhone 6s remains competitive at approximately $250.

What are the main components that contribute to the iPhone 6s production cost?

The iPhone 6s production cost is largely composed of various components, including $127 for semiconductors, $36 for cellular radios, $20 for 64GB flash memory, $25 for the A9 processor, and $73 for the screen, camera, and battery, among others.

Are there additional costs involved in the iPhone 6s production aside from parts?

Yes, in addition to parts, there are several manufacturing costs, including labor costs paid to assembly plants like Foxconn, which amount to about $8 to $11 per unit. Distribution and promotional costs also factor into the overall expense of producing the iPhone 6s.

Why is the cost to build the iPhone 6s lower than the retail price?

The iPhone 6s production cost of approximately $250 is lower than the retail price of $749 due to additional expenses that Apple incurs during manufacturing, marketing, and distribution. These costs ensure that Apple maintains its profit margins while delivering an advanced product.

What insights can we gain from the iPhone 6s price breakdown?

The iPhone 6s price breakdown reveals that most of the expenses are concentrated in specific components: $127 for semiconductors, $36 for radios, and $22 for advanced sensors, showcasing how Apple’s strategic sourcing influences the overall iPhone 6s production cost.

How has the iPhone 6s features affected its production cost?

Despite the iPhone 6s featuring advanced technology such as the A9 processor and 3D Touch, Apple has managed to keep production costs stable by integrating new components that do not significantly increase costs, highlighting their efficiency in manufacturing.

What can consumers learn about Apple manufacturing costs from the iPhone 6s?

Consumers can learn that Apple manufacturing costs for the iPhone 6s indicate a careful balance between cutting-edge features and cost efficiency. The estimated production cost of $250 reflects Apple’s ability to innovate without drastically increasing costs.

| Component | Cost ($) |

|---|---|

| Semiconductor Parts | 127 |

| Cellular Radios | 36 |

| 64GB Flash Memory | 20 |

| A9 Processor | 25 |

| Sensors (NFC, Fingerprint) | 22 |

| Screen, Camera, and Battery | 73 |

| Phone Case | 33 |

Summary

The iPhone 6s production cost is notably structured to ensure Apple maintains competitive pricing despite enhanced features. The estimated production cost for the iPhone 6s is approximately $250, reflecting a slight increase from the previous model. This strategic cost management combined with advanced components allows Apple to innovate without inflating consumer prices excessively. Consequently, the careful balance of component costs and production efficiency plays a crucial role in Apple’s pricing strategies in the smartphone market.